Below is a list of categories from which you can choose your favorite "V through "Z" button(s) to bring for "Show 'N Tell." If there is not a website link with the description, you can try google-ing the term and add the word "images" to find photos of the type. Also look for Vegetables, violets, Women, Yellow, etc..

Vegetable Ivory Buttons: Made from the nuts of the cores or tag palm. The vegetable ivory name was used to distinguish this nut “ivory” from tusk ivory. Nuts are about the size of a large egg and irregularly round. The nuts are kiln-dried for about 10 days and then the bark is removed by tumbling and hand cleaning. The best slices of the nut for buttons was closest to the bark. Buttons were dyed in vats and for multi-colored buttons, they were but on conveyor belts and dyed in succession. Vegetable Ivory buttons were decorated by embossing, stamping, crying, stenciling or with transfer designs. Large buttons are scarce and more valuable. www.buttoncountry.com/VI-1.html

Venetian Glass Buttons: These buttons somewhat resemble Venetian beads. A cane of glass is twisted over a glass button and generally, a wire shank is applied. Cone or dome-shaped tops. www.ebay.co.uk/itm/Vintage-Paperweight-Buttons-Venetian-Art-Glass-Roses-Mica-Green-Pink-Blue-/282648478592?hash=item41cf298380

Vest Buttons: In the 19th century, men’s vest buttons were made smaller than buttons used in the 18th century. Sometimes set with jewels, but more commonly decorated with molded glass, printed pictures under glass, etc. Shanks on men's buttons were usually larger than buttons worn by women (called jewel shanks). www.buttoncountry.com/GlassInM1.html www.ebay.com/itm/3A-Lot-3-Stunning-Waistcoat-Buttons-Pearl-w-Turquoise-Weskit-Glass-in-Brass-/263213449416

Victorian Buttons: Denotes a variety of different types of buttons made between 1850 and 1900. Molded glass buttons with raised designs and a lot of gold. Because too many buttons were made in this period, the term is not very effective and it is not used as often anymore.

Victorian Jewels Buttons: Large jewel buttons with glass centers that were made mostly for coats. Most have wire shanks; very few with self-shanks. Identical smaller versions of these buttons were also made so it can get confusing.

Volute Shell Buttons: These are now called Pinna Shell Buttons. Pinkish-brown in color and finely incised with line designs on their flat polished surface, which has been filled with silver, old or white paint. Made in the 19th century. 1/2” to over 2”. Can be scarce. (See photos from Button Country (NBS site) at end of list.)

Wafer Buttons: Wafer-thin buttons were made with flat glass fronts, metal backs and loop shanks. Between the glass and metal was usually a design — paper cutouts, tinsel, silver paint. 1/2” to 1”.

Waistcoat (Weskit) Buttons: In the 18th Century, mens’ waistcoats (vests) were heavily embroidered, buttons, as well. Buttons used on the trouser were the same size as the vests’ ones, so it is hard to tell where they were sewn on. However, very few embroidered buttons were used on pants. Shanks on 18th century buttons were heavier than what was made in the 19th century.

Wanamaker, John W. Buttons: Wanamaker was a merchant and his employees wore uniforms on which five different styles of buttons were used over the years. The name Wanamaker is on the back.

Washington Inaugural Buttons: Buttons made special for delegates to wear to George Washington’s inaugurals. Highly coveted! Hand-stamped coat buttons were large (in the fashion of the day) and made of copper, brass or Sheffield silver plate. Small buttons also made of those materials. Twenty-two different patterns have been found, five which were small. www.georgewashingtoninauguralbuttons.com/

Watch Crystal Buttons: Buttons with a glass face as thin as a watch crystal. Usually convex with a reverse-painted circles or flowers (rare with birds). Backs were flat metal disks with loop shanks. On the inside of the back, a cream-colored cement holds small pieces of pearl shell, which enhanced the overall effect.

Watchcase Buttons: A two-piece gilt button shaped similarly to the hunting case of a watch. They have a flat top with a very low-relief design. Backs are a little larger than the fronts.

Waterbury Button Company Buttons: Began in 1812 when Aaron Benedict began making bone and ivory buttons in Connecticut. In 1944, the company took the Waterbury Companies.

Waterbury Manufacturing Company Buttons: This firm was organized in 1814. The buttons have high relief designs and are of fine quality of workmanship and material…also very rare.

Waterville Manufacturing Company Buttons: (Waterville is a section of Waterbury). Fine sporting buttons marked on the back with the company name.

Wedge Shank Buttons: The flat or wedge-shaped shanks were cast or handwrought with the body of the button and then a hole was drilled by hand. Found on bronze, brass and white alloy buttons made in the 18th century. www.buttoncountry.com/BackTypes2.html

Weinman, Frank X. Buttons: Glassblower who began making paperweight buttons in the 1940s. Most were flat, slightly domed or cone shaped. The buttons were advertised as Aventurine Glass Art and are very rare.

Wessel Buttons: 1950s and 60s.Harry Wessel made enameled stainless-steel buttons with designs that were enclosed by glass. Tiny objects, flowers or pictures were put inside often almost like 18th century habitat buttons.

Whistle Buttons: Started with small two-piece chinas with a hole on top and two on the bottom. Now includes one-piece buttons with a hole on top and two on the bottom. When the button is sewn on, the thread becomes recessed, therefore protecting it from daily wear. Whistle buttons can be found in a wide variety of materials. Small china whistles range from less than 1/4” to nearly 1”. 1creativeone.wordpress.com/2009/07/10/fridays-favorite-whistle-buttons/

William Eaves & Sons Buttons: Mostly found are one- and two-piece gilt sporting buttons with the name on the back.

Williston and Knight Company Buttons: Mrs. Samuel Williston started making buttons with bone and wooden molds by hand in 1826. The company grew and expanded until it ended in 1922. Machine made buttons have been found with Samuel Williston and S. Williston on the backs.

Wire Mesh Back Buttons: Commonly called Screen Back Buttons, they were patented in 1873. Hot glass used in making the buttons was squeezes into the holes of the mesh, which made the glass stronger. The mesh is still obvious. Mostly used for black glass button making.

Women’s Land Army of America Buttons: Worn on the uniforms of officers of the Women’s Land Army of America, 1918-19. In the center of the round bronze buttons was a raised shield design in the shape of a “V” for victory. It enclosed WLAA in a banner motif over a sheaf of grain resting on a sickle. Rare.

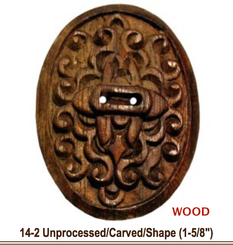

Wood Buttons: Almost every type of wood has been used to make buttons since at least the 18th century. As buttons age, it becomes harder and harder to determine what type of wood they were made from unless they are cut. 18th century wood buttons were plain and often featured pin-head shanks. in the 19th century were decorated more — inlaid with other woods or materials, carved, painted or trimmed. www.buttoncountry.com/Wood-1.html

Work-Clothes Buttons: Worn on jackets and coats called “jumpers,” which were made to wear over overalls. Sometimes called overall buttons. The button face is brass and the backs were usually made of iron, with black lacquer and a loose wire shank. Many have designs, names or slogans.

Zodiac Buttons: In the 20th century, zodiac symbols and signs have been very popular on buttons. www.buttons-boutique.com/sign-of-the-zodiac.html

RSS Feed

RSS Feed